Concrete

Placement

Train

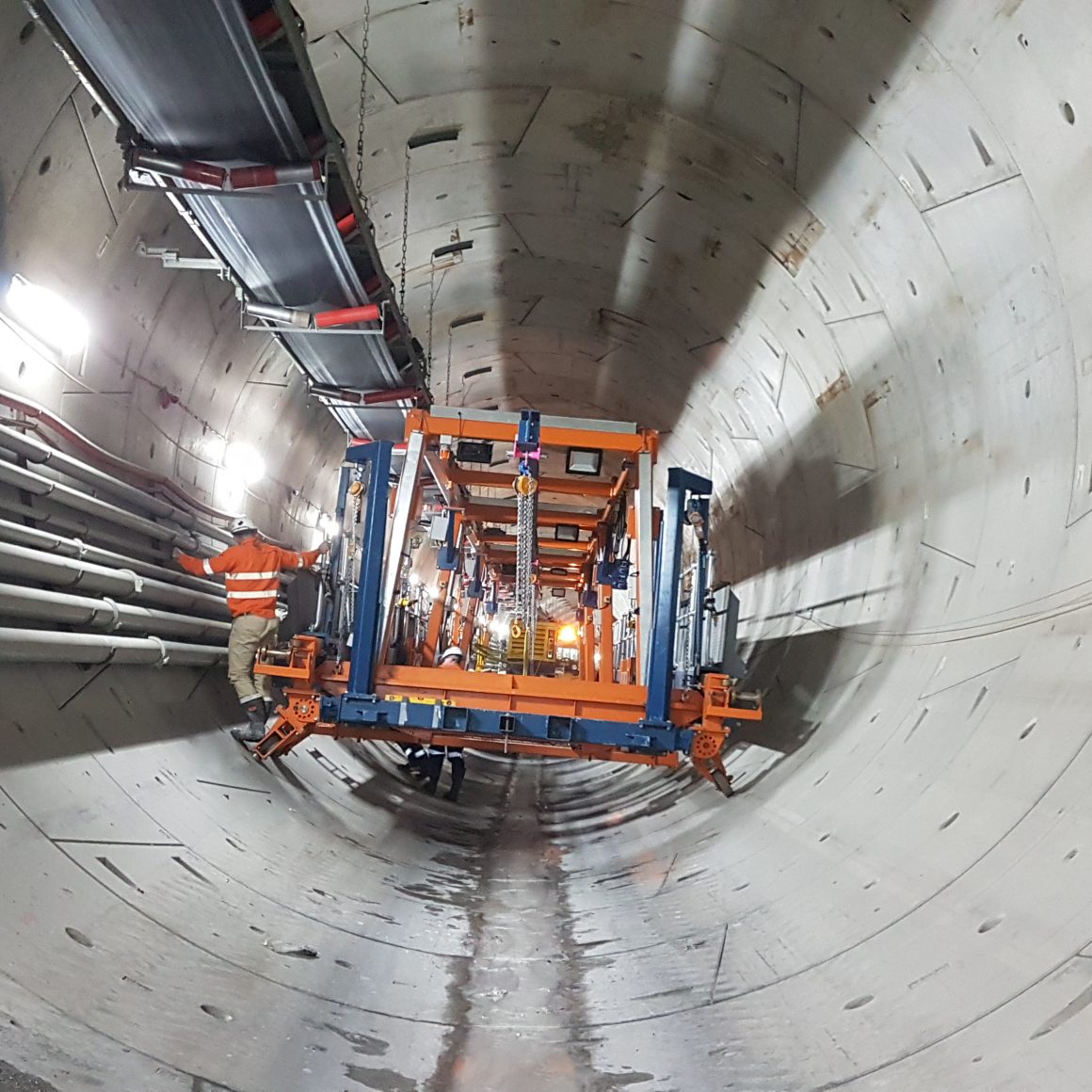

The CPT is a complete invert construction system that incorporates preparation, cast-in installation, placement, screeding and finishing. It is highly versatile, adapting for various invert designs and tunnel diameters. Throughout the development of the machine, our team has focused on the needs of both contractor and crew.

The concept of the CPT was developed by David Hume on the Melbourne Underground Rail Loop (MURL) project in 1975. It sat as an idea for years, it just needed a project.

Key Features

Production

The CPT is the fastest method of invert lining placement. The Machine will easily handle whatever rate of concrete is supplied to it.

Reduced Labour

Configuration 104-A: used on Melbourne Metro requires a crew of 6; to complete cast-ins, placement, screeding and finishing. Our latest machine further reduces this crew.

Self-Guided Steering

Our self-guided steering system allows it to travel at 0 degrees or to follow the super elevation. Manual steering is used for traversing obstacles and on flat ground.

Mechanised Finishing

We are currently developing tools to speed up the finishing process and reduce crew size.

Precision Screeding

Our screeds are versatile and effortlessly handle large volumes of concrete while forming nearly any profile. They adapt to variations in chord length caused by super elevation and ring build tolerances.

Flexible Delivery & Discharge

Multiple delivery and discharge options are offered, including agitators, dump trucks, conveyors or pipelines. Long line pumping simplifies underground logistics. Concrete can be received from the front or rear of the CPT. Forward placement facilitates concurrent preparation and placement for complex designs.

Adjustable. Portable.

The CPT navigates obstacles like cross-passage frames, equipment and tunnel services, allowing earlier start of invert works. It adapts to different tunnel diameters and heights, traverses flat ground, and quickly changes configuration with onboard jacks. In pack up mode, it’s narrow enough for completed stations and easily transported by truck between sites.

Safety Features

Other Features

- Fully enclosed hand rails according to AS 15578

- Pedestrian and plant segregation

- Ergonomic, adjustable work platforms

- Wide walks that fold up in pack up mode

- Comprehensive general and task lighting

- Electrical installation to international standards

- The CPT is both a methodology and machine enabling a continuous steady output. As such, worker fatigue is greatly reduced

- Enabled safe transit of the workforce across the fresh concrete

- CPT. Safe. Comfortable. Easy

- Transported by truck to site - fully assembled

- High quality materials, machining and fabrication

- Dual monorail allows equipment to pass through

- Operated by remote

- Elevated, telescoping plant decks containing power pack, tanks, etc. These are lower-able for ease of servicing

- Pack-up mode ensures the width is below 3.1m wide allowing standard transport

- Easily transportable and able to fit in shipping containers

- Accepts a wide range of mixers; not possible with other systems

- Bosch Rexroth Hydraulics

- Capable of placing the track slab with minor configuration changes

Find out more:

[minigo-button text=”Download our brochure” url=”http://www.ucsglobal.com.au/wp-content/uploads/2024/06/UCS-CPT-Brochure-EP.pdf” class=”” style=”btn–medium”]